Solutions for energy storage systems (ESS)

From an idea

to a finished

project

In 2021, MKC Group of Companies signed an agreement on the exclusive distribution of products across MENA (the Middle East and North Africa region) for the preparation of energy storage projects with an engineering company whose team for more than 5 years has been engaged in the design, production, implementation, certification and post-sales support of a complete set of energy storage systems based on CATL lithium batteries, including battery cabinets with BMS, power converters with transformers, EMS, container solutions with climate control and fire extinguishing systems.

The successful global experience of implementing storage systems is about 0.5 GWh for 2020-2021 and will be increased to 1.5 GWh in 2022. A number of pilot projects for the introduction of storage devices in the United Arab Emirates is being jointly prepared.

Currently, MKC Group of Companies has concluded a list of agreements and is implementing them within the framework of a joint production and service enterprise in the UAE, an exclusive distribution agreement for the design, trade and post-service maintenance of energy storage devices based on CATL battery solutions.

Lifetime cost management

Due to such characteristics as high reliability, long service life with the possibility of extended warranty, high energy efficiency of CATL battery systems, hybrid power plants based on renewable energy sources with battery cells for its storage can accelerate the energy transition to decarbonized methods of electricity generation.Operation of the ESS alongside with generation

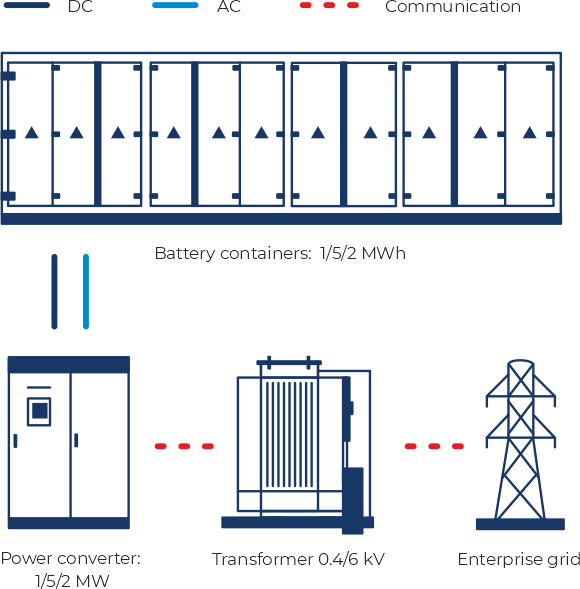

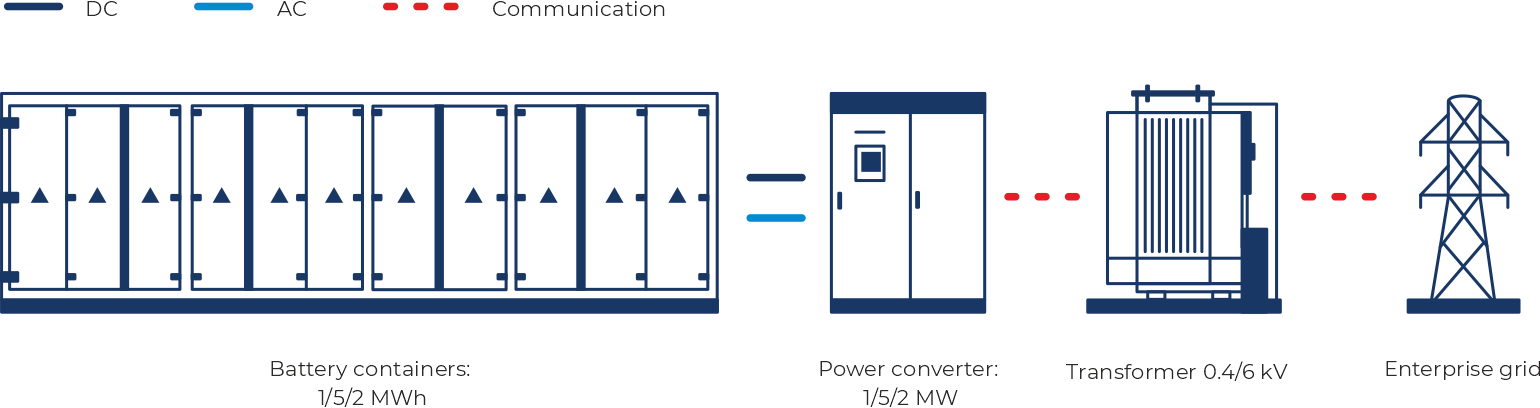

CATL battery-powered energy storage systems provide energy storage and flexibility in power generation. Instant utilization and energy output due to battery electrochemical technology and the technology of electricity production using gas-piston units can be combined into a single most efficient system. Thanks to the high-level consistency of battery cells due to the BMS control system, CATL battery solutions can ensure the stability of the power system, optimize the curve of electricity generation, reduce interruptions in the operation of renewable energy sources, ensure the inertia of the system and the functions of frequency and peak modulation, increase the share of renewable energy sources in total electricity generation and optimize the energy structure of an enterprise.Operation of the ESS in parallel with the network

CATL energy storage systems provide smart load management when working in parallel with the network, instantly modulate the frequency and peaks depending on the load on the external network. In this case, the ESS performs the functions of increasing and expanding peak power, backup power functions and smoothing consumption peaks. ESS helps to ensure safe, stable, efficient operation of the power system and optimize the cost of electricity by smoothing power peaks.

Electrochemical energy storage devices with CATL battery solutions are successfully used in large industrial and commercial enterprises, residential areas, and are also being extended to new scenarios, such as fast high-power electric vehicle charging stations, backup power sources (BPS), autonomous and island/isolated systems due to network-forming converters. Such applications help enterprises in the absence of an electric grid to get access to electricity (together with generation based on gas-piston power plants operation), reduce electricity costs and ensure stable operation of the electric grid.

The main components of the ESS

- Block container (module) with engineering climate control systems;

- Management subsystem;

- Energy distribution subsystem;

- Energy conversion subsystem;

- Energy storage subsystem;

- Docking output;

- Auxiliary docking terminal;

- Matching transformer.

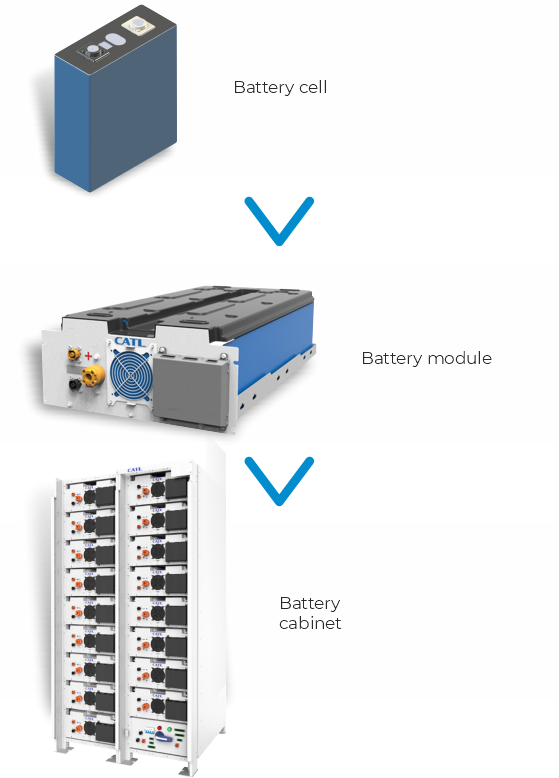

The standard 280 Ah battery cell and 1088 V CATL battery cabinet, conforming to UL1973, UL9540A standards.

| Battery Cell Parameters | |

| Cell Type | CATL LFP |

| Rated voltage | 3,2 V |

| Operating voltage | 2,8 ... 3,6 V |

| Rated capacity | 280 Ah |

| Rated power consumption | 896 Wh (@25°C, 1C/1С) |

| Operating temperature, charge | 0 ... 55°C |

| Operating temperature, discharge | –20 ... 55°C |

| Weight | ~ 5,34 kg |

| Dimensions (L x W x H) | 71,7 x 173,9 x 207,2 mm |

| Battery Module Parameters | |

| Connection | 1P20S |

| Rated voltage | 64 V |

| Voltage range | 56 ... 72 V |

| Rated capacity | 280 Ah |

| Rated power consumption | 17,92 kWh (@25°C, 1C/1С) |

| Operating temperature, charge | 0 ... 55°C |

| Operating temperature, discharge | –20 ... 55°C |

| Cooling | Air cooling |

| Weight | ~ 140 kg |

| Dimensions (W x D x H) | 516 x 950 x 234 mm |

| Battery cabinet parameters | |

| Connection | 17 battery modules in sequence + 1 control module |

| Rated voltage | 1088 V |

| Operating voltage range | 952 ... 1224 V |

| Rated capacity | 280 Ah |

| Rated power consumption | 304,64 kWh (@25°C, 1C/1С) |

| Maximum continuous current | 280 A |

| Operating temperature, charge | 0 ... 55°C |

| Operating temperature, discharge | –20 ... 55°C |

| Weight | ~ 3000 kg |

| Dimensions (W x D x H) | 1200 x 1040 x 2300 mm |

| BMS | 2 levels |

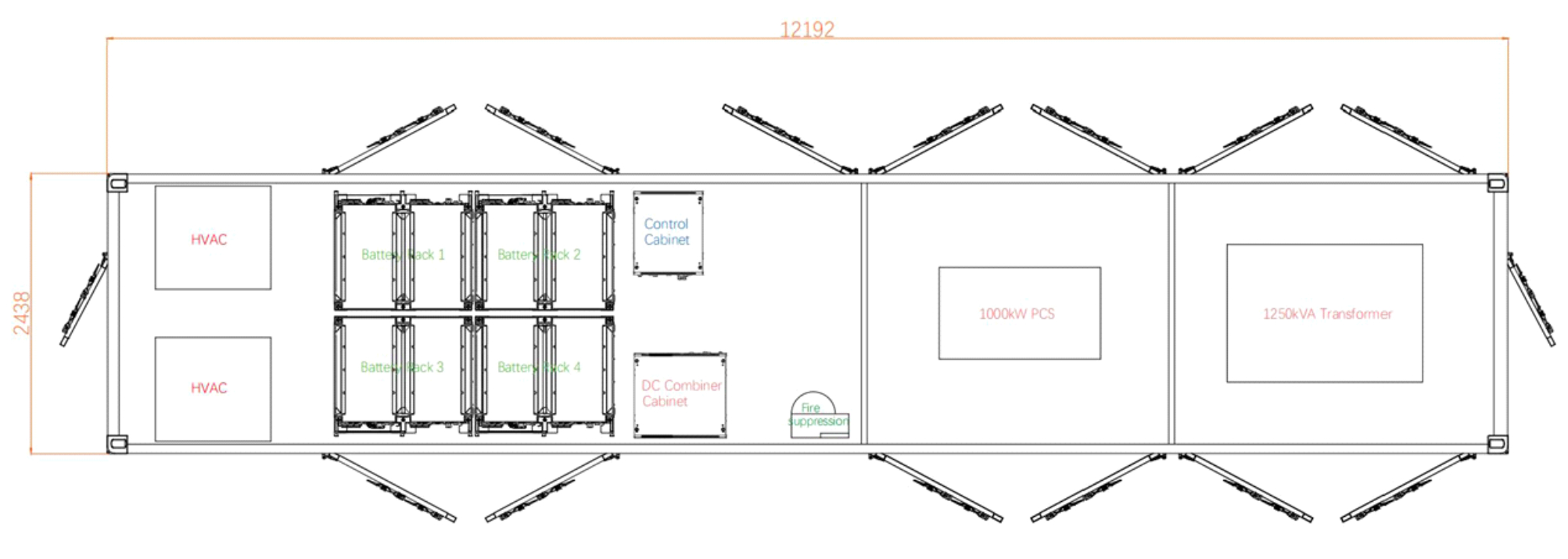

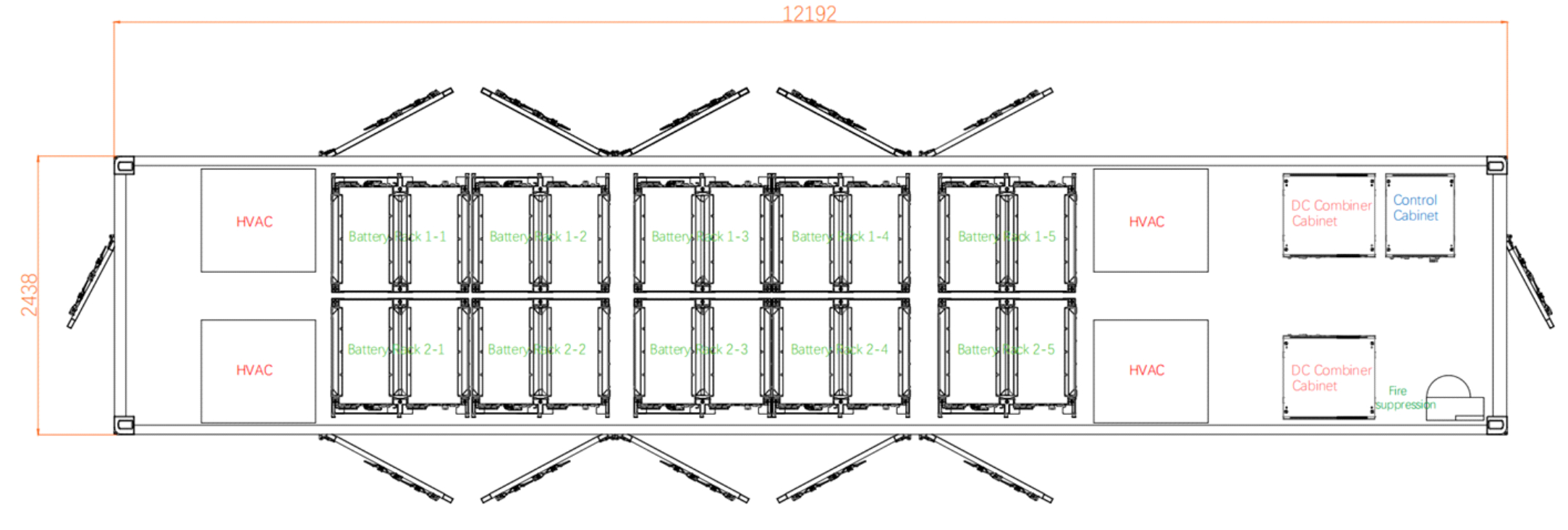

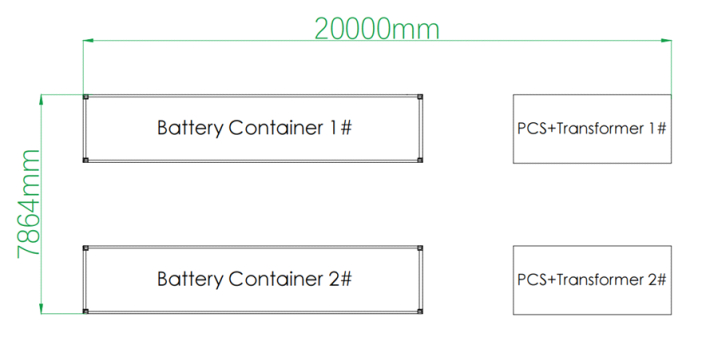

| Container Project Parameters | |

| Design | The general view of the container in the image is preliminary, provided for reference only |

| Rated voltage | 1088 V |

| Voltage range | 952 ... 1224 V |

| Rated energy | 1,22 ... 3,04 MWh (@25°C, 1C/1С) |

| Location in the container | 4-10 battery cabinets connected in parallel, 1-2 DC unifying cabinets, 1 control cabinet |

| Operating temperature, charge | 0 ... 55°C |

| Operating temperature, discharge | –20 ... 55°C |

| Cooling | Air cooling |

| Storage device placement | 40" container |

| BMS | 3 levels |

| Power Converter Parameters | |

| Maximum input current | 1603 A |

| DC voltage range | 700 ... 1500 V |

| Rated AC output power | 1100 kVA |

| Output operating voltage | 440 V AC |

| Network frequency range | 50 Hz |

| Efficiency | 99,03 % |

| IP level | IP20 |

| Type of cooling | Smart air cooling |

| Operating temperature | –35 ... 60°C |

| Dimensions (W x H x L) | 1400 x 2000 x 800 mm |

| Weight | 1300 kg |

| Charger Parameters | |

| Design | A charger with a transformer can be made in a separate container |

| Maximum input current | 3206 A |

| DC voltage range | 700 ... 1500 V |

| Rated AC output power | 2000 kVA |

| Full AC power | 2200 kVA |

| Output operating voltage | 440 V AC |

| Network frequency range | 50 Hz |

| Efficiency | 99,03 % |

| Rated transformer power | 2000 kVA |

| Voltage transformation coefficient | 0,44/6 kV |

| Transformer Type | Oil/Dry |

| IP level | IP55 |

| Type of cooling | Smart air cooling |

| Operating temperature | –35 ... 60°C |

| Dimensions (W x H x L) | 5670 x 2525 x 2462 mm |

| Weight | 13000 kg |

Block module of the battery block is equipped with a fire automation system

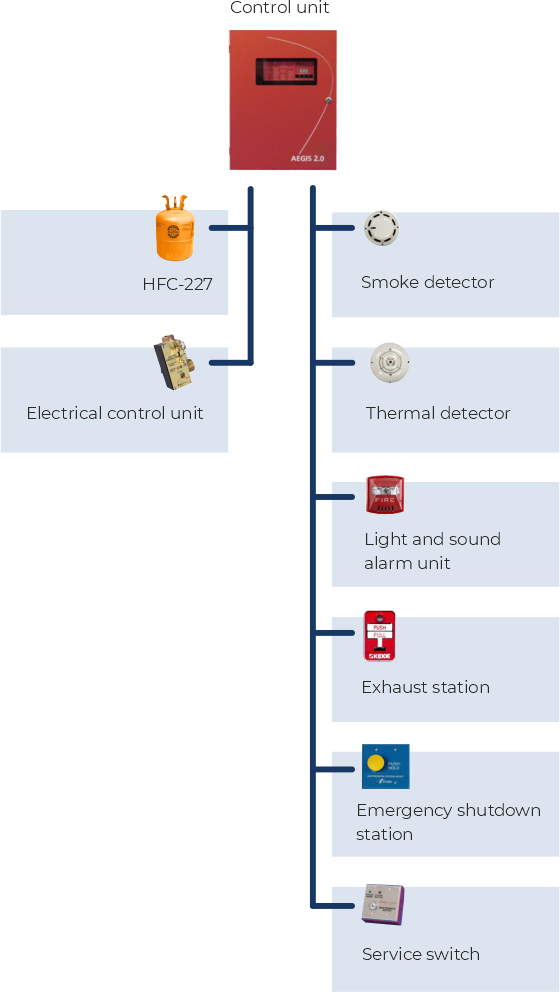

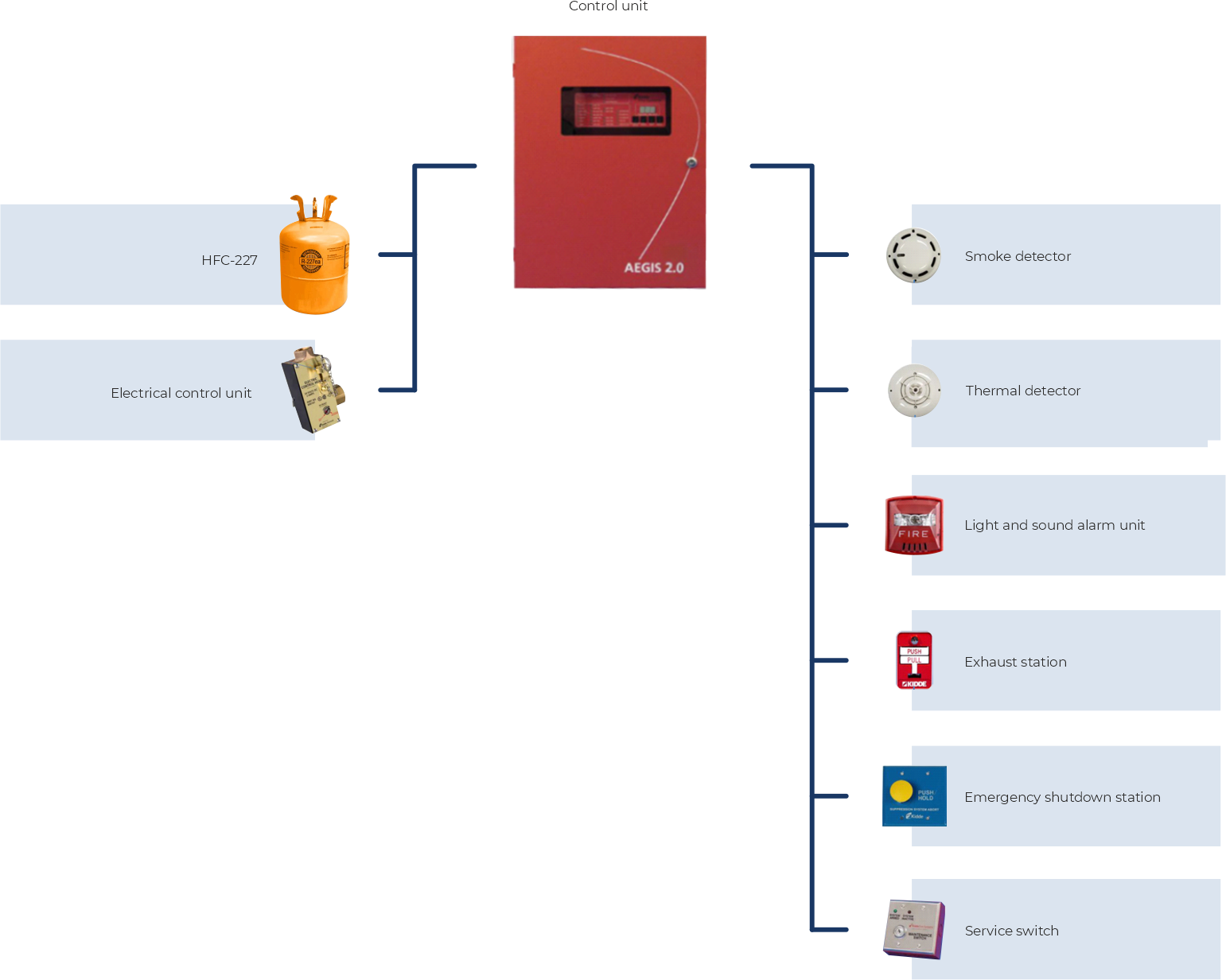

The fire protection system includes an automatic alarm system and a fire extinguishing system. The automatic alarm system consists of a control unit, a thermal detector, a smoke detector, an exhaust station, an emergency shutdown station, a light and sound alarm unit, an alarm signal, and a light indicator.