Trigeneration solutions

MKC Group of Companies offers best trigeneration solutions, integrated production of electric power, heat and cold. Trigeneration provides for an opportunity to utilize efficiently the recovered heat not only for heating in winter, but for air conditioning and technological needs of the enterprise is summer as well. Absorption refrigerating systems are used for it. Such an approach allows the year-round operation of a gas genset unit without reducing its high efficiency in summer period when demand for the generated heat is reduced.

Trigeneration technology is actively applied in oil&gas industry, metal processing, chemical industry, at cold storage facilities and dairy plants, as well as at the facilities having centralized heating, ventilation and conditioning systems, such as business centers, trading malls, distribution centers (food storage facilities), data processing centers, hospitals, hotels, airports, etc.

Heat

Power

Cold

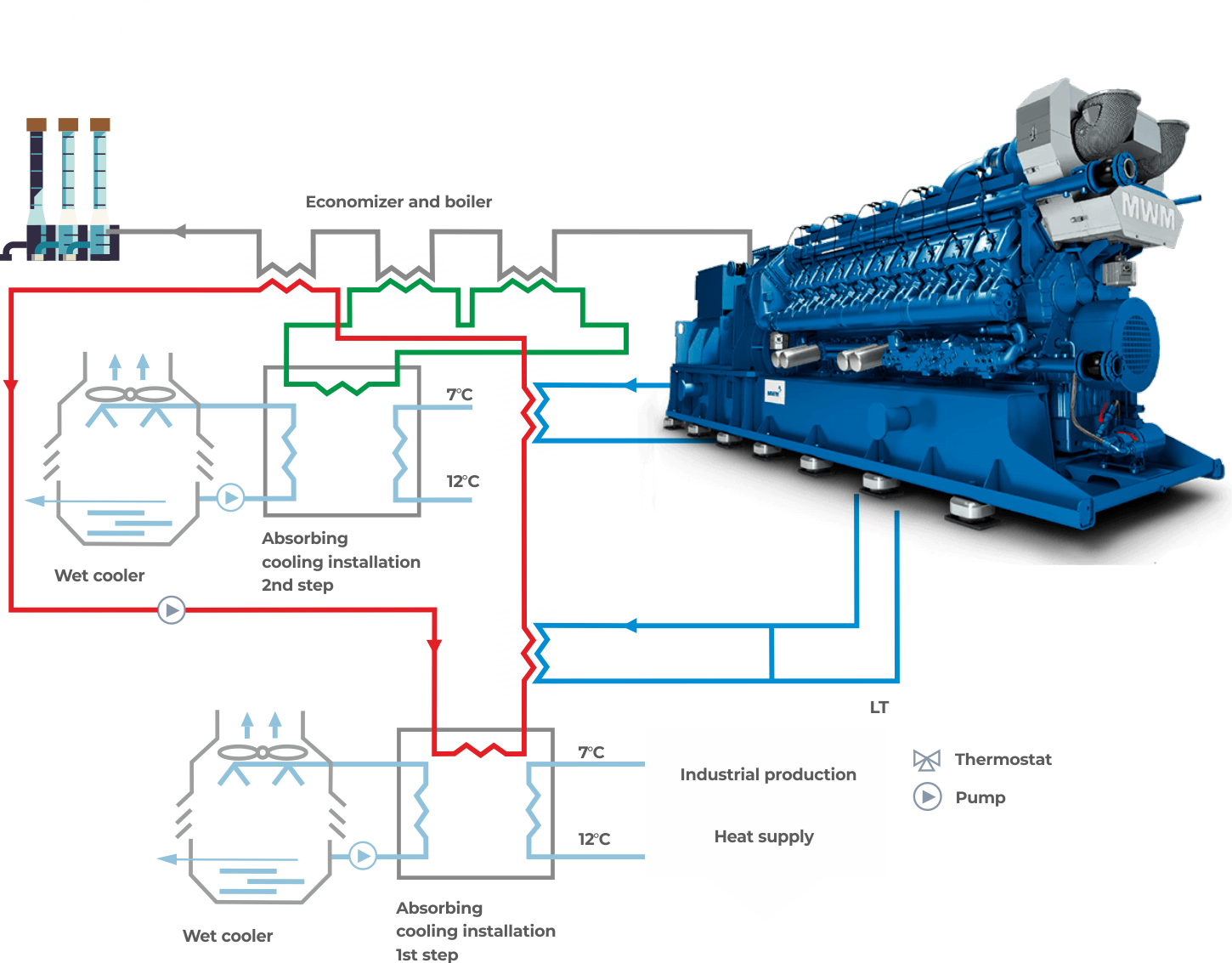

Trigeneration is a process using a part of the heat energy generated by the operation of an internal combustion engine for water cooling, air conditioning or refrigeration. Technologically the diagram of trigeneration can be illustrated as a combination of a cogeneration unit and an absorption refrigerating system.

Trigeneration Diagram

(absorption chiller) is an industrial cooling unit designed for collecting and recovery of the waste heat and supporting preset preferable temperature conditions during operation of the equipment and technological processes related to high thermal loads. Various solutions are used as absorbing agents in absorption refrigerating systems (for example, lithium bromide LiBr).

The absorption refrigeration system is heated by hot water or steam. The process can consist of one or two stages. One stage process allows generation of 600 kW of cold per 1 MW of electrical power, two stages process ensures production of 1200 kW.

Absorption refrigeration systems have two operation modes intended for generation cold and heat. Adsorption chiller operating in adsorption/desorption cycles and allowing use of heat power of not very hot water (80–50°С) stay out. They are relevant for Southern regions where the demand for cold is higher and there is not enough electric power, especially during periods of peak loads.

The possibility of generating heat energy during the heating season and producing cold in summer period makes exploitation of a trigeneration unit economically viable. This technology ensures full load the gas genset engine without any downturns in heat energy consumption outside the heating season.