LOW-TONNAGE

METHANOL PLANTS

One of the promising areas of MKC Group of Companies work is the implementation of projects for the construction of low-tonnage plants for the production of methanol from natural or associated petroleum gas. These compact mobile facilities, located directly near shale oil and gas fields, enable the customer not only to gain additional competitive advantages by obtaining new products, but also to significantly reduce the negative impact on the environment by reducing the volume of hydrocarbon flaring.

WORLD-

CHANGING

TECHNOLOGIES

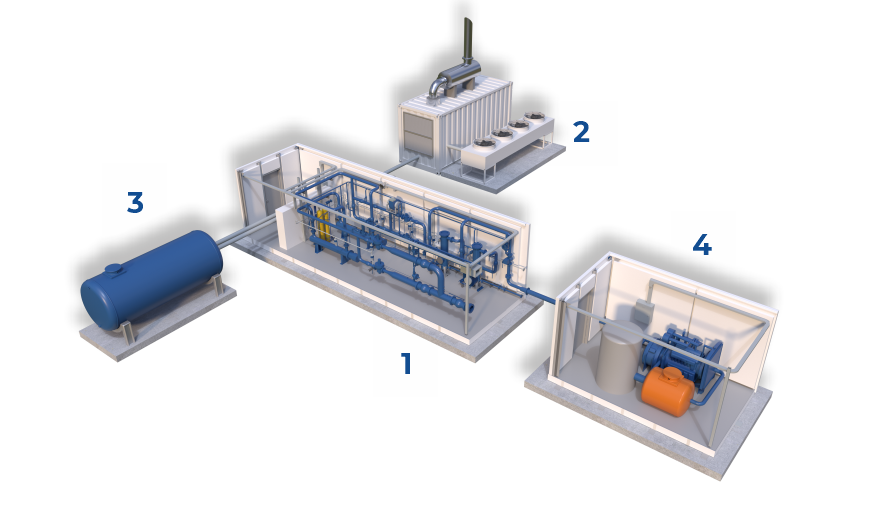

When implementing projects for the construction of low-tonnage methanol plants, MKC Group of Companies performs all works "turnkey": from engineering surveys, design, equipment supply to construction, installation, facility commissioning and handover into operation. The project is implemented by the technology of block-modular construction. The entire complex is located in two standard 20-foot containers, excluding finished products storage. This makes it easy to move the object between fields with minimal commissioning period.

1

Ejector CTL reactor in a standart 20-foot container

2

Steam generator

3

Storage tanks for final products

4

Gas treatment and purification system

Characteristics of the standard module:

- Methanol capacity – 80 tons/day or 25,000 tons/year (taking into account production losses and service maintenance of the plant)

- Daily consumption of natural gas - 100,000 m3 (3000-5000 m3/hour)

- If performance needs to be improved, number of modules can be increased

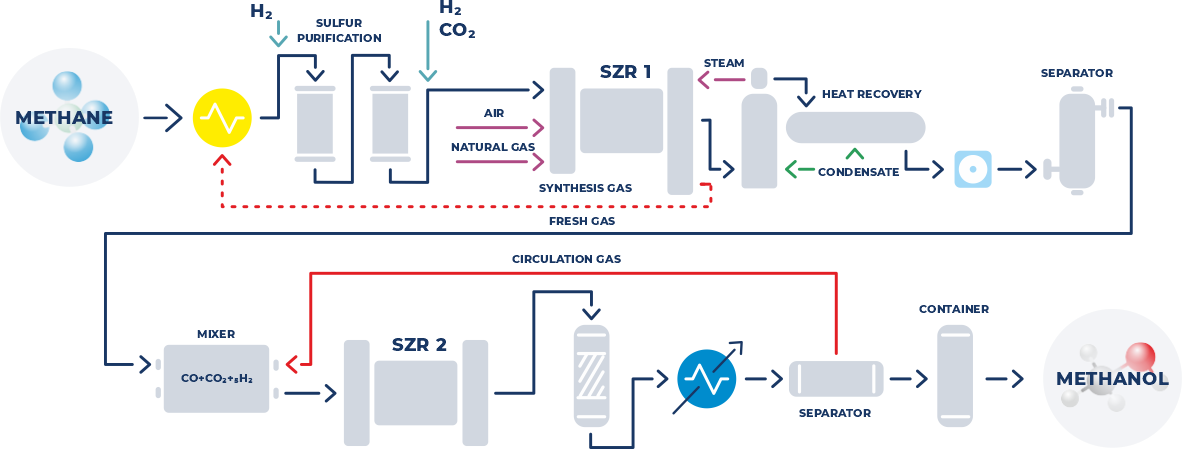

About technology

Methanol production technology offered by MKC Group of Companies is a combination of innovative approaches and classical methods of gas processing. Using advanced scientific developments in the field of gas flows and the study of substances in the transition state between the liquid and gaseous phase (supercritical fluids), MKC engineers managed to significantly modify the technology of gas-liquid conversion. As a result, the volumes of reaction zones have decreased tenfold, and the speed and parameters of conversion reactions and methanol synthesis have increased manifold. At the same time, installations safety has been significantly increased due to its small dimensions.Ejector GTL reactor

Low-tonnage methanol production plants performed by MKC Group of Companies are suitable for both oil and gas companies and industrial methanol consumers. The MKC plants provide an opportunity to gain additional competitive advantages by reducing the cost and obtaining new types of products that meet all modern environmental requirements. The location of low-tonnage MKC plants for methanol production in shale oil and gas fields changes the production cost and business due to the reduction of transport arm and the production of highly liquid products directly on site.

Advantages of low-tonnage plants in fields:

Reduced volume of hydrocarbons flaring. As a result: reduction of penalties amount.

Production of a high-value product (methanol) without laying a pipeline or creating LNG production facilities. As a result: increased profitability of fields.

Refusal or a significant decrease of methanol import to the fields for technological needs. As a result: increased profitability of the field; reduced environmental risks of transportation; autonomy and independence from fluctuations in methanol prices.

The installation is fully automated, has an integrated remote monitoring and control system. As a result: reduced operating costs for personnel.

Methanol, also known as methyl or wood alcohol, is a liquid, flammable, organic substance. It can be produced from natural gas, coal and renewable sources such as garbage, biomass and recycled carbon dioxide. Methanol is one of the most important ingredients that can be used to produce many types of industrial and consumer products. About 40% of methanol in the world is used in energy sector.

The main advantages of these projects performed by MKC:

Methanol is a high-demand product in petrochemistry for polypropylene production, for which there is a steady growing global demand

Methanol is used for gas extraction and transportation

The cost of methanol production is 100-120 dollars per ton, sale price is 300-500 dollars per ton

Fast production and commissioning time

There are technologies, own production, engineering

IRR projects service more than 30%