Construction of Power Plants

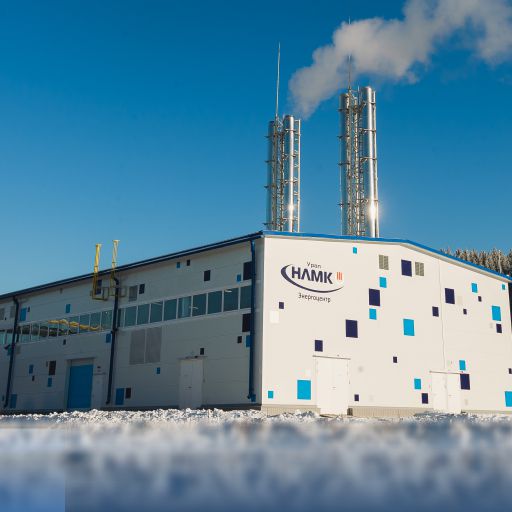

MKC Group of Companies is a leading producer of gas genset power plants of both stationary and modular execution. Our main competitive advantage is turnkey power plants construction. We offer integrated power supply services for enterprises from survey and design works to commissioning and servicing of a facility. By today, MKC Group of Companies has commissioned 53 turnkey modular power plants in various countries. Total capacity of implemented projects amounts at 300 MW.

We build

modular

power plants

turnkey

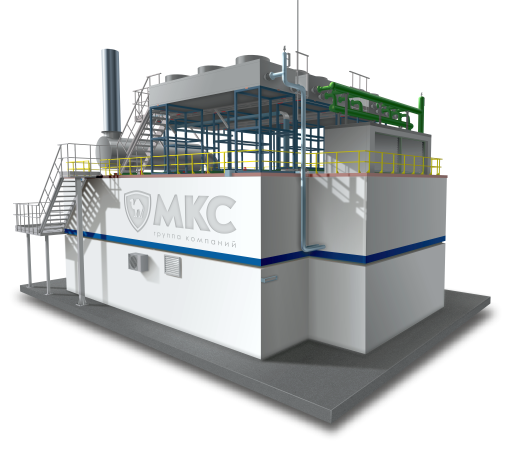

We offer services for construction of both stationary (in a building) and modular (containerized) power plants. Construction technology depends on the technical requirements. One of the benefits we provide is our own production facilities for manufacturing of modules (containers) and packaging of gas genset units of various capacity.

Turnkey

Engineering

is our general approach

Turnkey Engineering is our general approach. MKC Group of Companies performs the whole scope of a gas genset power plant construction from design and constructional engineering to commissioning and servicing of a facility. Such an approach ensures quality control at each stage and significantly reduces the total cost of the object.

We offer the whole range of a power plant construction services:

Design

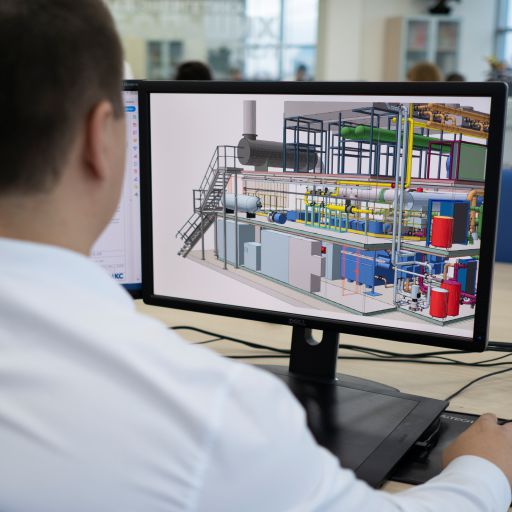

Carrying out the survey and design works is one of the most important stages of gas genset power plant construction. This is the stage for MKC Group of Companies’ specialists to work out the major technical solutions, develop and approve design documentation, create visualization of an object.

2

Approval

Construction of a power generating facility involves a large scope of work on coordinating the project with numerous supervisory agencies. MKC Group of Companies settles down all the issues related to authorities, supervisory bodies, natural monopolies and guides the project over the whole period of its implementation.

3

Equipment supply

Depending on the customer’s requirements, specialists of MKC Group of Companies agree the specification of the main generating equipment, a gas genset unit, supply volume. Being an official dealer and service partner of MWM, MKC Group of Companies offers the best prices and shortest delivery terms for the brand’s equipment.Manufacturing

At this stage MKC Group of Companies specialists package generating equipment, produce bearing and fencing structures (including the modules themselves), manufacture auxiliary equipment. All the equipment is delivered to the customer’s site at its maximum operational readiness.

5

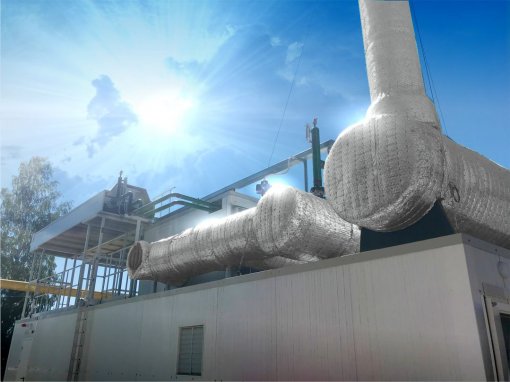

Construction and installation works

Performing of construction and installation works at the customer’s site by MKC Group of Companies include following types of work: earthworks, foundations, construction of buildings and structures, installation of technological equipment, installation of modules, construction of linear and network facilities, construction of access roads, landscaping, etc.Commissioning

Adjusting is the final stage of the project implementation. At this stage MKC Group of Companies’ specialists carry out comprehensive testing and launching of the generating equipment. The major task of commissioning is testing all operation modes of a gas genset unit at idle and under load, ensuring that the equipment reaches its rated operating parameters.

7

Dispatching and monitoring

At the request of the customer, MKC Group of Companies can carry out real time remote dispatching and monitoring of the generating equipment operation from a single dispatching office. Such a service improves reliability of a gas genset power plant operation and allows to promptly react to any deviations in the equipment performance.Service

A gas genset power plant operation is a complicated task requiring sufficient competencies and high technical level of employees from its owner. Therefore, in most cases the owners of gas genset power plants conclude contracts for service maintenance of a generating facility with MKC Group of Companies. Being an official dealer and service partner of MWM, we offer the best prices and shortest delivery terms for spare parts.Own gas genset power plant brings profit! One of the main criteria for construction a gas genset power plant is reducing the cost of energy supply. The cost advantage of operating a gas genset power plant is connected to locating a generating facility in close proximity to the consumer: power is supplied at the cost of electricity generated, which is much lower than the market purchase price.

Own

gas genset power plant

brings profit!

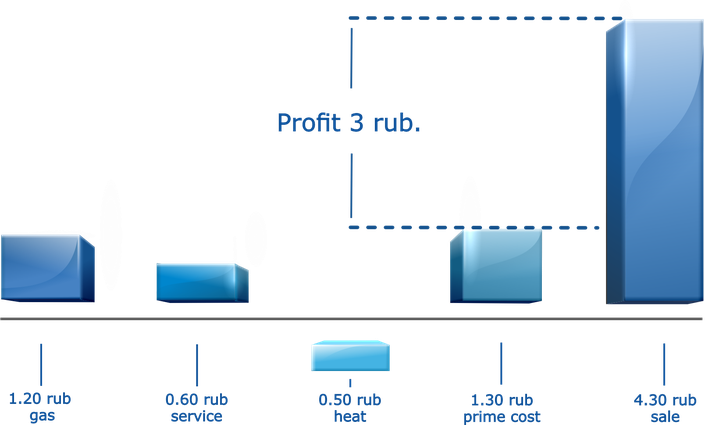

The diagram shows an approximate structure of a unit cost and cost advantage of using an MKC Group of Companies’ gas genset power plant for a consumer. As a result, the consumer can get electrical power at a price much lower than that of the default provider.

In this regard, gas genset power plants implementation projects now have quite an attractive for a consuming enterprise payback period of up 5 years. Moreover, implementation time of such projects by MKC Group of Companies generally fits in one calendar year. From this point of view, implementation of a gas genset power plant project is not only an affordable but also an apparently cost efficient and logical step.