Gas Treatment Units

The MKС Group of Companies is a manufacturer of innovative fuel gas preparation units (FGPU). These devices are intended for production of fuel gas from associated petroleum gas (APG) with quality corresponding the requirements to the gas-genset power plants' fuel per the methane index and calorific value. FGPU by the MKС Group of Companies comply with all the technical standards, have low weight and overall dimensions, low operating costs, are easy to operate and maintain, are reliable and efficient in operation.

The Fuel Gas Preparation Unit (FGPU)

The Fuel Gas Preparation Unit (FGPU) is designed to produce fuel gas from associated petroleum gas (APG) with quality corresponding to the gas genset power plants' fuel requirements per the methane index and calorific value. The FGPU meets all technical standards, has low weight and overall dimensions, low operating costs, is easy to operate and maintain, reliable and efficient in operation.

Designation

One of the associated petroleum gas (APG) utilization methods is its application as fuel for autonomous gas turbine and gas genset power plants providing cheap electric and heat power to the constructions at remote fields.

Direct APG use as a fuel gas for the gas genset power plant without proper preparation results in power plant's capacity loss and in the engine wear. In order to achieve the declared power station capacity, a number of requirements must be fulfilled. Apart from the traditional requirements for mechanical impurities cleaning and dew points (water and hydrocarbons) provision, the MPP manufacturers also impose requirements to the blend composition and methane number of the fuel gas. In order to obtain fuel gas of required quality, the MKС Group of Companies has developed a modular FGP unit.

Technical characteristics

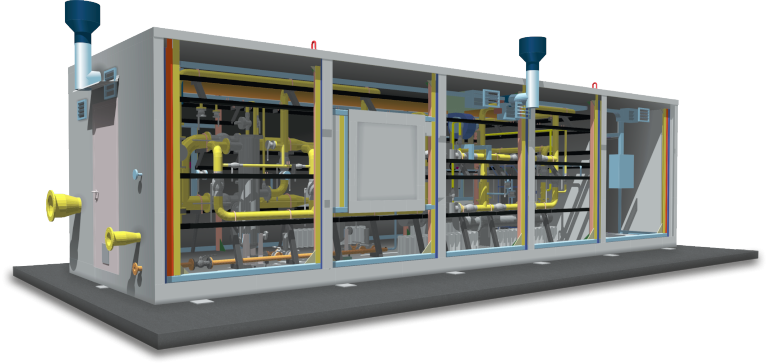

In order to ensure the possibility of transportation and movement from site to site, the FGPU is supplied in the form of modules with dimensions not exceeding those of the standard sea container. The FGPU by the MKС Group of Companies is supplied as one unit. A set of two units (compressor and heat exchange) is also possible.

Preliminary gas preparation unit equipment set:

- gas preparation unit;

- propane cooling unit mounted on the screw compressor;

- deethanization unit;

- single-wall LHG reservoirs of 150 m3 volume (applied as LPG);

- automatic filling system with LHG taking into account product output;

- reagent dosing unit;

- piping of the unit with process pipelines;

- block automatization;

- compressor station consisting of piston compressors;

- debuthanization unit.

Due to the fact that different fields may show considerably different gas compositions, the plant is developed with high fuel gas quality control potential. For each gas composition the heat exchange surface is recalculated, and the compressor unit is selected. Low temperature APG separation is used to ensure high quality fuel gas. Gas purification from mechanical impurities and drip moisture is carried out at the patent louver packs separators. Gas drying is performed by means of adsorbers. The issue of the heavy hydrocarbons, produced at the APG preparation, utilization is solutioned jointly with the customer individually in each specific project.

Comparative gas blend composition chart

| № | Gas component | Designation | Original gas composition, molar fractions, % | Fuel gas composition, molar fractions, % |

| 1 | Methane | CH4 | 57,84 | 82,19 |

| 2 | Ethane | C2H6 | 16,62 | 12,61 |

| 3 | Propane | C3H8 | 14,48 | 2,99 |

| 4 | i-Butane | (CH3)3CH | 2,17 | 0,12 |

| 5 | n-Butane | CH3(CH2)2CH3 | 4,41 | 0,13 |

| 6 | i-Pentane | (CH3)2CHCH2CH3 | 1,17 | 0,04 |

| 7 | n-Pentane | CH3(CH2)3CH3 | 1,22 | 0,03 |

| 8 | Nitrogen | N2 | 1,13 | 1,71 |

| 9 | Сarbon dioxide | CO2 | 0,18 | 0,15 |

| 10 | n-Hexane | С6H14 | 0,65 | 0 |

| 11 | Heptane | C7H16 | 0,12 | 0 |

| 12 | Octane | C8H18 | 0,01 | 0 |